What are cone crushers?

Cone crushers are among the most versatile and useful pieces of aggregate crushing equipment. There are plenty of manufacturers offering high-quality cone crusher options for your business. Take a closer look at different cone crusher manufacturers so you can narrow the field and select the best equipment.

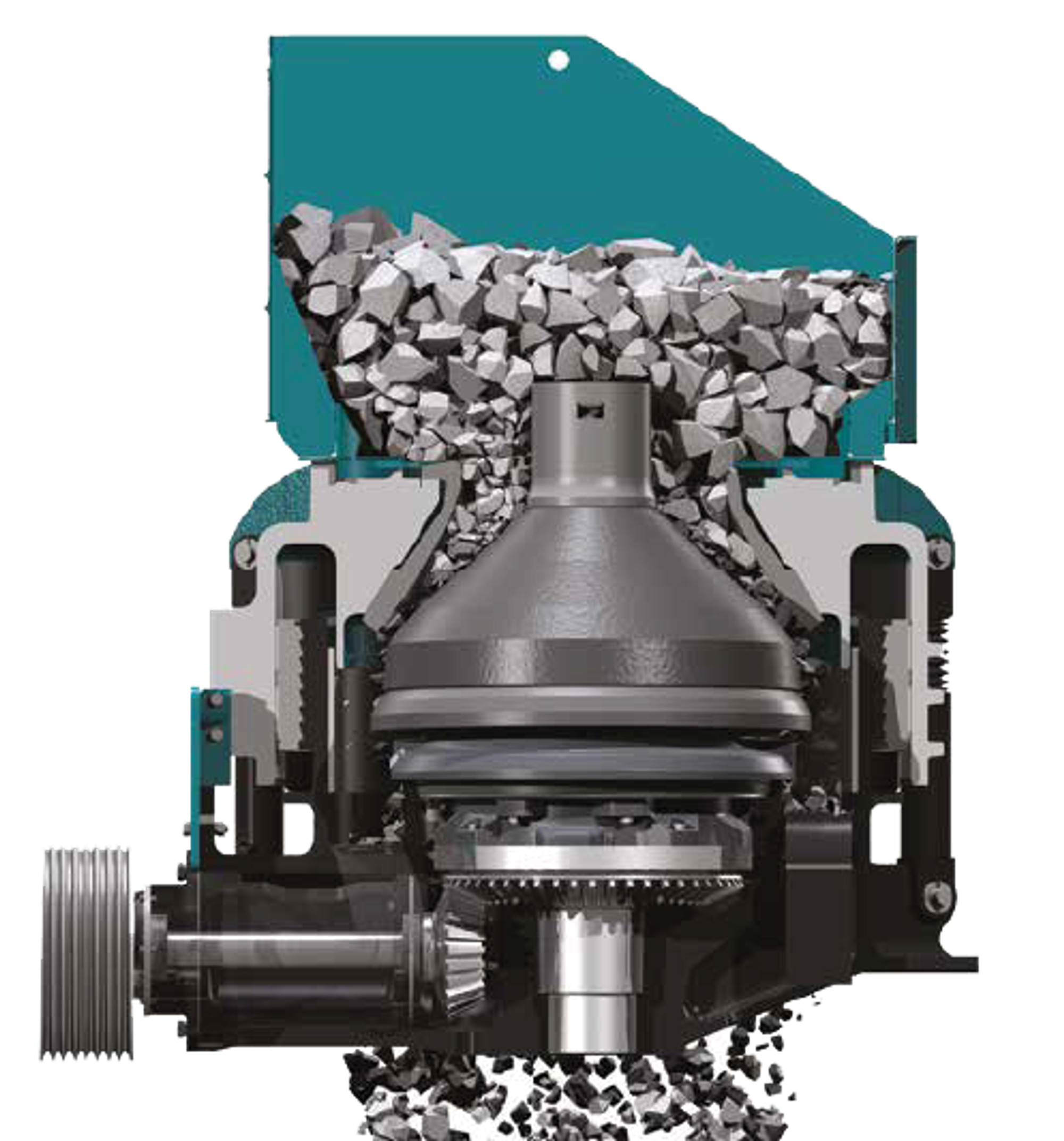

The Cone crusher uses a unique combination of gyration and eccentric throw to produce extremely high crushing force and free flow of material. Production levels are unsurpassed and mean lower power consumption per ton, according to the manufacturer, MSP Engineering.

Stones are crushed against each other, which breaks the material down further. This concept is known as interparticle crushing and is used by many companies to make their products stronger.

Cone crusher in action

The ultimate cone crusher directory

McLanahan

The McLanahan Cone crushers are built heavier than most competitive Cone Crushers. The extra weight means lower stress on the machine, which results in longer operational life. A unique and patented feature allows the Liners to fit without the use of any backing material. Improved Chamber matching with crusher feeds virtually eliminates any trial and error.

Finlay a Terex Brand

The Finlay range of cone crushers provide flexibility, high rates of productivity and excellent product shape in secondary and tertiary applications. They are renowned for their capabilities in crushing mid-hard and above mid-Hard ores and rocks as well as hard ores and rocks.

Sandvik

Sandvik’s provide you maximum value in terms of performance, quality, safety, flexibility and — not least — total economy. No matter the application, we'll ensure you're matched with the right solutions to maximize your productivity and profitability. We help you meet your production targets in smarter, faster and more cost-efficient ways.

Superior

Superior's Patriot Cone Crusher is one of the world's most powerful bushing cones. Bushing cones are made up of rotating mantle inside a steel bowl. As rock is compressed between the mantle and the bowl, the force generated fractures the material. This process continues until pieces are small enough to fall through the bottom.

Getting in the details

The power input imparted by the driven eccentric results in a bearing force in opposition to the crushing force at a point on the main shaft. The distance between the bearing force and fulcrum point is called the force arm.

This is a detailed view of the bushing bearing, which carries all of the vertical component and part of the horizontal. The long force arm, represented by the main shaft, reduces the load transmitted through the eccentric bushing. Crushing loads are distributed over a large spherical bearing; the socket liner keeps full contact with the crushing head ball.

Capacities and product gradations produced by Cone Crushers are affected by the method of feeding, characteristics of the material fed, speed of the machine, power applied, and other factors. Gradations and capacities are most often based on a typical, well-graded choke feed to the crusher.

The importance of sampling

Knowing the size distribution of your raw material will help you produce a more consistent final product. It's essential to sample throughout the crushing process so you can ensure that the crusher can maintain an optimal level of productivity. Sampling becomes especially crucial if there are any changes in upstream processes that may affect feed size or distribution.